SpiraLithCa™ CO2 Absorbent

The First Major Advancement in CO2 Absorbent Technology Since 1924

SpiraLithCa™ CO2 Absorbent consists of absorbent powder bound together by a polymer matrix to form a solid sheet of absorbent. The sheets are specifically designed with precision pre-formed air passages that eliminate channeling and ensure uniform cartridge use and longer duration.

SpiraLithCa™ CO2 Absorbent eliminates all the issues of granules, offering significant benefits for clinicians, technicians, and hospitals. Because of its chemistry and solid construction, it performs more predictably, lasts longer, is better for the environment, and provides increased safety for patients, staff, and equipment. SpiraLithCa™ is also safe to use at all flow rates…how low can you flow?

Traditional absorbents are composed of dusty, loose pellets or granules that shift and settle, which leads to channeling where expired air takes the path of least resistance, creating random channels that become exhausted long before the rest of the absorbent is consumed. This dust is very invasive and finds its way into the anesthesia machines, breathing circuits, filters, and patient airways. Eliminating the dust means increased patient safety and decreased overall costs.

SpiraLithCa™ CO2 Absorbent Advantages

SOLID ABSORBENT TECHNOLOGY = BETTER PERFORMANCE

FINALLY!

DUST ELIMINATED

Dusting is a problem inherent with ALL granular absorbents, well-known to cause many complications, having a direct and negative impact on patient safety, anesthesia costs, machine health, and the time and efforts of hospital staff, particularly anesthesia providers, technicians, and biomedical engineers.

SpiraLith’s unique, solid absorbent technology eliminates all dust related complications and ensures:

- Patients are no longer at risk of inhaling caustic dust during surgery.

- Diminished biomedical service calls and rescheduled surgeries due to machine pre-test failures.

- Reductions in disposable part replacement costs, such as sensors and o-rings.

- Easier, less time-consuming machine servicing.

- Superior shock and vibration resistance prevents dust creation during shipping and handling.

NO CHANNELING

Channeling occurs in granular absorbents when gas takes the path of least resistance. This problem causes prematurely exhausted product, significant waste, and inferior duration.

Spiralith’s solid absorbent technology uses engineered, uniform flow pathways to eliminate channeling:

- SpiraLith Ca absorbs CO2 more efficiently resulting in superior duration compared to all other CO2 absorbent.

- Reduced environmental impact with fewer canisters and less unreacted absorbent in the waste stream.

- Molded flow channels reduce duration variability, providing consistent, reliable performance.

- Color change can be relied on to determine product exhaustion and remaining life.

LOW FLOW SAFETY

Traditional granular absorbents are known to degrade volatile anesthetics and produce toxic byproducts, including Compound A, Carbon Monoxide, and Formaldehyde, thus preventing clinicians from utilizing low flow anesthesia. Several absorbents have eliminated these concerns by removing KOH and reducing NaOH concentration to <2%.1 However, these changes severely impact product duration and frequency of disposal.

SpiraLith Ca utilizes <1% NaOH and eliminates concern for toxic byproducts. When this chemistry is packaged with Solid Absorbent(r) technology there is no duration penalty. In fact, SpiraLith Ca duration is superior to all granular absorbents.

SpiraLith Ca allows clinicians to safely and cost-effectively utilize low-flow anesthesia and its benefits:1

- Humidification of inspired gasses, resulting in better infection fighting capabilities, higher core body temperatures, less lung damage, and fewer post-operative complications.

- Dramatic reduction of volatile anesthetics and their associated costs.

- Further reduction of volatile anesthetics entering landfills and the environment (disposed cannisters contain residual agent)

1. Feldman JM, Hendrickx J, Kennedy R. Carbon Dioxide Absorption During Inhalation Anesthesia: A Modern Practice. Anesthesia & Analgesia. April 2021, Vol. 132, Issue 4, p 993.

EASIER USE & LOGISTICS

- SpiraLith Ca is manufactured in the United States, eliminating supply-chain complexity and reducing risk.

- Sales and clinical support readily available by phone, text, or email.Unlike granular absorbents, SpiraLith Ca quality does not deteriorate during shipping and handling.

- SpiraLith Ca requires changing less frequently than any other CO2 absorbent.

- SpiraLith Ca has the only color indicator system which predicts remaining absorbent life.

- SpiraLith Ca eliminates dust related biomed calls and rescheduled surgeries from machine pre-test failure.

- Anesthesia workstations utilizing SpiraLith Ca require less service time and fewer replacement parts.

- SpiraLith Ca is safe for low-flow anesthesia.

SUPERIOR DURATION & REDUCED COST

Differences in CO2 absorbent formulations can translate into significant performance differences, and the choice of absorbent should not be based on unit price alone.1

Although priced higher than competing absorbents, SpiraLith Ca’s superior performance provides the opportunity to achieve significant reductions in overall cost of anesthesia delivery:

- Highest CO2 absorption capacity, efficiency, and longevity.2

- Most consistent performance (least variation).2

- Elimination of dust related service calls and rescheduled surgeries.

- Safely reduce anesthesia costs utilizing low-flow anesthesia.

1. Feldman JM, Hendrickx J, Kennedy R. Carbon Dioxide Absorption During Inhalation Anesthesia: A Modern Practice. Anesthesia & Analgesia. April 2021, Vol. 132, Issue 4, p 993.

2. Jiang Y, Bashraheel MK, Liu H, et al. In vitro efficiency of 16 different Ca(OH)2 based CO2 absorbent brands. J Clin Monit Comput. 2019;33:1081–1087.

BETTER FOR THE ENVIRONMENT

Everyone is aware of the global efforts to reduce the amount of plastic and chemicals entering our environment. Inhaled anesthetics are known to deplete the ozone layer and the health care sector accounts for 8% of total U.S. greenhouse gas emissions with operating rooms generating 20-30% of total hospital waste1.

SpiraLith Ca provides an opportunity to significantly reduce environmental footprint:

- SpiraLith Ca’s superior duration and decreased frequency of cannister changes mean users contribute significantly less plastic and chemicals to our landfills.

- SpiraLith Ca’s is safe for low-flow anesthesia, meaning users can significantly reduce inhaled anesthetics entering our atmosphere.

1 Axelrod, et al. Task force on Environmental Sustainability Committee on Equipment and Facilities. Greening the Operating Room and Perioperative Arena: Environmental Sustainability for Anesthesia Practice, Revised October 2014.

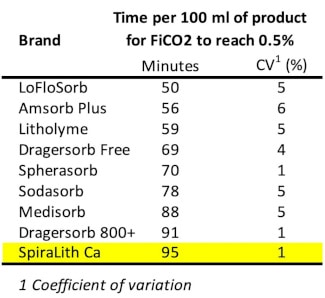

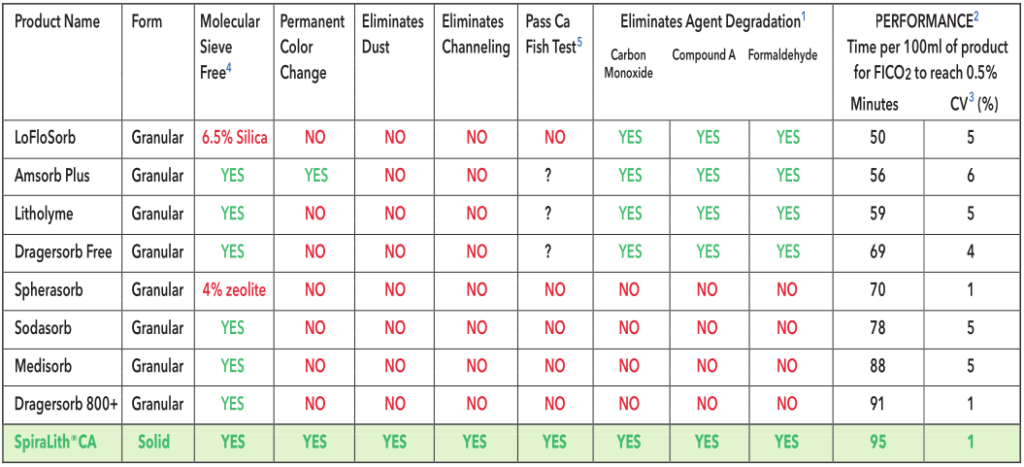

Performance and Composition of Competing Absorbents

SpiraLith®Ca’s unique composition and superior performance provide the opportunity to achieve significant reductions in overall cost of anesthesia delivery, while simultaneously improving patient safety and reducing environmental footprint:

- Far superior CO2 absorption efficiency without performance variation (see table above)

- Elimination of dust problems and channeling, along with fewer product changes reduces utilization of clinician,technician, engineering, and nursing time and efforts, especially related to biomed service calls and surgery rescheduling due to anesthesia machines failing their pre-use tests.

- Reduction in anesthesia costs due to ability to utilize low flows for extended periods of time without worries of Compound A, Carbon Monoxide, or Formaldehyde production

- Permanent, reliable, consistent color change increases user confidence and decreases waste

- Significant reductions in environmental footprint and waste; far fewer canisters are discarded and those that are have a much higher percentage of their chemical contents reacted than traditional granular absorbents, which will have remaining absorption capacity ranging from 13.5% to 73.3%, with a mean of 44.8%.6 Additionally, SpiraLith®Ca satisfies California State’s strict requirements for disposal as non-hazardous waste.5

REFERENCES AND FOOTNOTES

1. Independently published scientific literature.

2. Jiang Y, Bashraheel MK, Liu H, et al. In vitro efficiency of 16 different Ca(OH)2 based CO2 absorbent brands. J Clin Monit Comput. 2019;33:1081–1087.

3. CV: Coefficient of variation is used to calculate the consistency and uniformity of data. Higher numbers represent greater volatility and variability, while lower numbers represent greater consistency and reliability. SpiraLith®Ca users can expect superior performance each and every single time.

4. Olympio, M. Carbon Dioxide Absorbent Desiccation Safety Conference Convened by APSF. The Official Journal of the Anesthesia Patient Safety Foundation. Volume 20, No. 2, 25-44. Summer 2005. www.apsf.org.

5. CCR Title 22 – Fathead Minnow Hazardous Waste Screen Bioassay (Polisini and Miller 1988).

6. Franklin V. Cobos II, M.D., Max T. Baker, Ph.D., John H. Tinker, M.D. Department of Anesthesiology, Nebraska Medical Center, Omaha, Nebraska. Discarded Soda Lime; Economic & Practice Implications. Anesthesiology 2004; 101: A567.

Rx-2903C Instructions For Use – Drager with Clic® adapter

Rx-2719C – Rx-0719A Instructions For Use – GE

Instructional Videos

New Color Indicator Window

- Helps predict when inspired CO2 approaches 0.5%

- Bold, fade-resistant color

- Uses 1000X less ethyl violet compared to granules

The First ever Color indicator Window System

Color Windows enable you to see inside the cartridge